My grandmother used to make puddings for Christmas in February; I think that gave her time to add plenty of brandy!

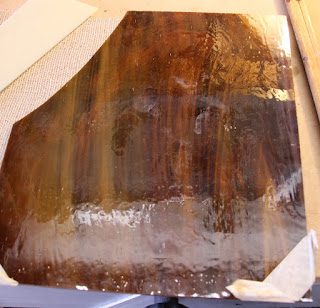

I've a couple of craft fairs lined up for the next month or so and I thought of her when I was going through my offcuts shelf recently, for I found a piece of brown/multi colour (fairly) opaque glass that I think I used to represent stone on my image of Bingley church:

I got to thinking whether I could make up some passable Christmas Pudding suncatchers (or tree decorations). I had several offcuts of opaque white to represent sauce (or icing); after playing with a cardboard template for a while I cut out a couple of samples and edged them in copper foil.

I ended up soldering another length of 0.4mm wire beside the loop, trimmed the holly and made a hole with a hot needle, and secured the sprig to the pudding by threading the wire hrough the hile and around the berries.

The one without the bottom run of solder (left above) is as solid as the other one; so long as it isn't biffed too much, or allowed to get too wet, it should hold together fine.

I did also experiment with adhesives (epoxy resin and UHU) to secure the holly to the glass but neither stuck well to the flexible plastic holly; both puddings therefore have been decorated using the soldered-wire-through-the-hole fashion, and are ready for the punters at the craft fair in Biggleswade on November 13th, and I've enough materials to make another eight by then (not all in the brown colour though) !

Rather than edge the brown glass to mate with the white in a single plane, I've chosen to plate the white over the brown disc. One sample has copper edging all round; on the other I've just edged those edges I'm going to solder - the appearance of the final piece, without a solder edge between the white and brown, may be better than that with, at the possible expense of strength - I'm not sure how well the piece without the supportive soldering will hold together.

I tinned these pieces using my 80w iron (itself tinned using multicore solder - it seems to be more effective for tinning irons than normal 60/40 solder and separate flux). I use plumbers flux paste, so, after tinning, the pieces were washed thoroughly, dried lightly with a towel, and despatched to the airing cupboard to dry off thoroughly.

Note to the unwary: failing to dry off all water after washing and before the next step (more soldering) will, very quickly, teach you why you should wear safety glasses when soldering!

Once dry, I soldered the pieces together and added a 4mm diameter loop of 0.4mm silvered copper wire, bought from a craft stall at Hitchin market. I also found some plastic decorative holly, meant for cake decoration - the only challenge with that was how to fix it to the puddings.

The one without the bottom run of solder (left above) is as solid as the other one; so long as it isn't biffed too much, or allowed to get too wet, it should hold together fine.

I did also experiment with adhesives (epoxy resin and UHU) to secure the holly to the glass but neither stuck well to the flexible plastic holly; both puddings therefore have been decorated using the soldered-wire-through-the-hole fashion, and are ready for the punters at the craft fair in Biggleswade on November 13th, and I've enough materials to make another eight by then (not all in the brown colour though) !