Leaded panels need occasional maintenance (as does everything, of course ... despite what salesmen will tell you, uPVC sealed unit windows require maintenance and have a finite life, which is much shorter than the 100+ years a properly fitted leaded panel will last!). If this very occasional maintenance is carried out leaded panels will last a very, very long time indeed, and will be watertight, and will withstand anything the weather can throw at them; they'll also cope with a small amount of building movement far better than a rigid single pane (or aforesaid uPVC windows!).

I recently looked at these panels in a church porch:

The first thing to note is that, from a distance, they look to be in good condition, and there are two saddle bars supporting each panel. So long as the fixings are sound there should be little movement in the panel, so the next step is to check for this by gently pressing on the middle of the panel.

In this case only a small amount of movement was perceptible. (If there had been more than about an eighth of an inch - 3mm - it would show that the seal between the cement and the glass had failed completely, which would allow water ingress, and would only get worse when movement is forced in a strong wind, or due to traffic vibration.)

The next step to check the condition of the cement is to tap many of the lights (glass pieces) and listen to the sound produced: if it is a single 'tap', that indicates that the panel is sound, all pieces being firmly held together, but if there is a rattle, it indicates something is loose and needs to be made secure. (This holds true for ordinary windows, including double glazed units, too.)

One panel in the church porch produced a slight rattle, but the others were all sound. A close inspection of the 'rattly' panel showed some cement to be loose,

and also that several of the soldered joints in the panel had failed.

I suspect that someone had leaned on the panel from inside the porch at some point in the past: a short term fix for this panel would be to apply fresh leaded light cement to all of the leads, which will help to keep the rain out and prevent further deterioration of the building fabric. Such a fix could be done by a DIY-er and would probably last maybe ten years, since the saddle bars are holding the panel firm; long term the panel needs some soldering which may involve it being removed from the building, but that can be planned for a time when other maintenance is being carried out.

Inspecting the panels on the other side of the porch I found one broken light - a small hole, almost too small to be the result of wanton vandalism. The glass was firmly retained in the leads, and there was no need to replace it immediately. (To replace it would involve damaging the leads to such an extent that the repaired panel would look no better than it does now; a better solution could be to use clear epoxy to glue a piece of plain glass on the inside of the broken light to keep the rain out, if needed). In the very short term a piece of sellotape can be used to cover the hole just to keep wind and rain out.

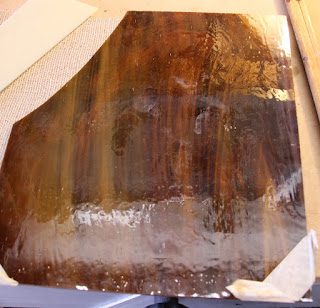

Structurally, the panels were quite sound - I was quite surprised, bearing in mind they were installed in 1937 and have probably received no maintenance since then. The leads were showing some sign of corrosion - as with roof flashing, lead in windows will oxidise over time, developing a white surface. To slow down the process boiled linseed oil can be applied to the leads; the right hand side of the panel below has been treated in this way:

In addition, linseed oil applied maybe once every ten years helps to stop the cement losing adhesion on the glass, thus prolonging the life of the panel.

Much of the above can be done by householders or building owners themselves and does not require any specialised skills.